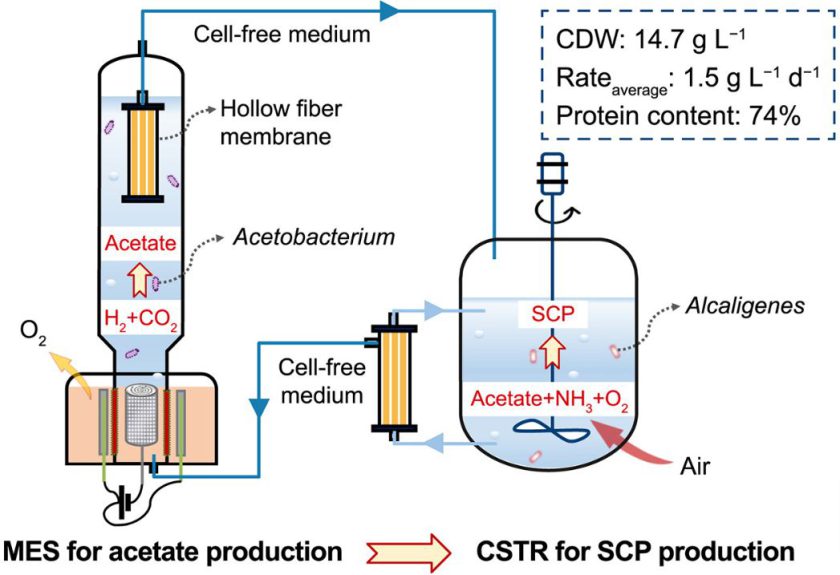

A team of Chinese researchers have designed a dual-reactor system, which has the potential of transforming carbon dioxide (CO2) into a consumable single-cell protein, offering a sustainable solution for food production.

So how does this system work?

First Stage: Microbial electrosynthesis converts carbon dioxide into acetate, it is performed in the following three steps:

- Electrochemical Process: An electrical current is initiated that gives to specific microbes.

- Microbial Activity: These microbes, under the influence of applied electric current initiate a chemical reaction that transform CO₂ into acetate.

- Acetate Production: The biochemical process transforms or creates acetate, which is a simple organic compound that can be used as a building block in further stages of the system.

Here, the microbes make use of CO₂ as their primary source of carbon, rather than usual sugars or other organic compounds.

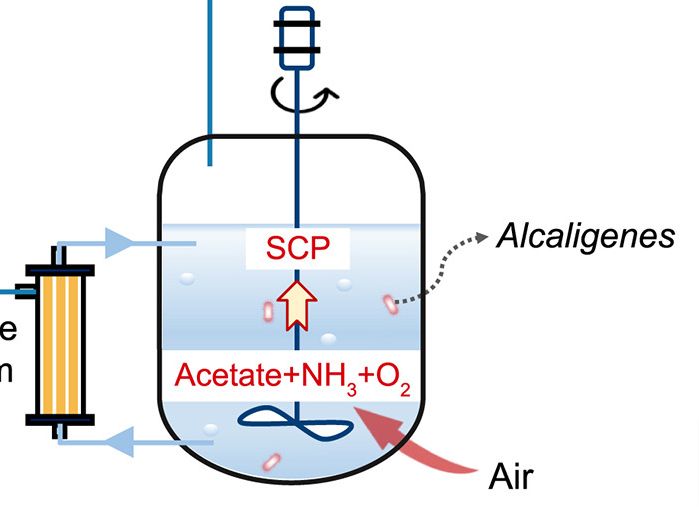

Second Stage: The acetate that was produced in the previous step is used here as a nutrient or a source of carbon. It is then mixed with aerobic bacteria. Acetate becomes their primary source of carbon and energy while using oxygen to power their metabolism. Eventually, these bacteria grow and multiply, forming biomass, which consists of the cells of the bacteria themselves.

The biomass is saturated with protein, amino acids and other nutrients, this eventually makes it a single-cell protein product. The resultant protein rich product can be ingested by humans or animals, as it offers a potential food solution while recycling CO₂ from the atmosphere.

Key Features of the Process

Overall, the process has several notable features:

- The system achieved an efficiency of 17.4 g/L of dry cell weight, which means, after all the water has been removed, this much amount of dry bacterial cells or biomass were generated.

- The resulting protein or the total weight of dry biomass has a concentration of 74%. This value surpasses both soybean (typically has a protein content of 40 – 50%) and fish meal (typically has a protein content of 60 – 72%).

- The produced protein is suitable for both animal feed and human consumption.

- The system requires minimal pH adjustment, which simplifies the process and reduces costs. Many biotechnological processes involve adding acids or bases to maintain a stable environment, this system, however, is designed in a manner that it functions efficiently without the need for such adjustments – which makes it easier to operate on a large scale.

- It also generates less wastewater, making it more sustainable and cleaner. This system minimizes the amount of wastewater generated, which translates to fewer resources being wasted, and so less pollution and more environmentally friendly.

Takeaway

Researchers envision that their dual-reactor system can resolve the problem of food scarcity at global level and at the same time the entire process can be carried out by generating significantly less the atmospheric carbon dioxide. They also pointed out the nutritional efficacy of this protein is for both people and animals.

The research indeed looks promising in sustainable protein production, who knows, it could actually be a game changer for environmental and food security challenges that we are experiencing today. As we dive into such interesting ideas like this, it’s worth considering: Could this tech be the way we produce food around the world in the future?

More information: Zeyan Pan et al, Single-Cell Protein Production from CO2 and Electricity with A Recirculating Anaerobic-Aerobic Bioprocess, Environmental Science and Ecotechnology (2025). DOI: 10.1016/j.ese.2025.100525