Super-thin and flexible electronics are here to stay. This tech will not only create but it will also revolutionize the use of gadgets. Since, it leads to unlimited possibilities for innovative and practical applications. Some of the them include but not limited to – wearable tech, portability, healthcare applications, space probes etc.

However, there is one major drawback to the current flexible electronics: they are built on plastic films. This can pose a significant issue, especially for wearable sensors. The plastic coating can block gas and moisture from passing through, which can be problematic. Although there are gas-permeable artificial skins available, they still interfere with normal sensations and often require energy-intensive and wasteful manufacturing processes.

Thin, Adaptive Electronic Fibers for Seamless Integration on Biological Surfaces

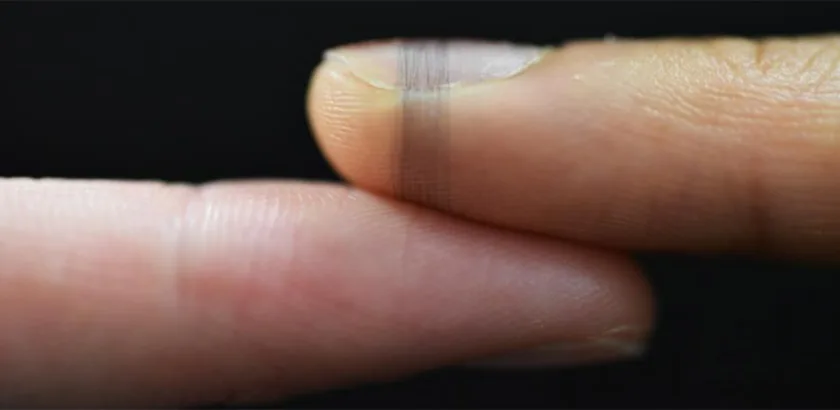

Researchers at the University of Cambridge have found an intriguing solution to this problem. They’ve developed a method for creating adaptive and eco-friendly sensors that can be seamlessly printed onto various biological surfaces. Whether it’s a human finger or a delicate flower petal, these sensors can be applied directly and indiscernibly, thus, opening up exciting possibilities for their use.

The technique draws inspiration from spider silk. The team’s synthetic silk is embedded with bioelectronics. The idea is to enable integration of diverse sensing functionalities directly into the material.

These fibres are about 50 times thinner than human hair. If we talk about its weight, well, it’s so light that the researchers were able to install it on the delicate seedhead of a dandelion, without collapsing its structure, of course.

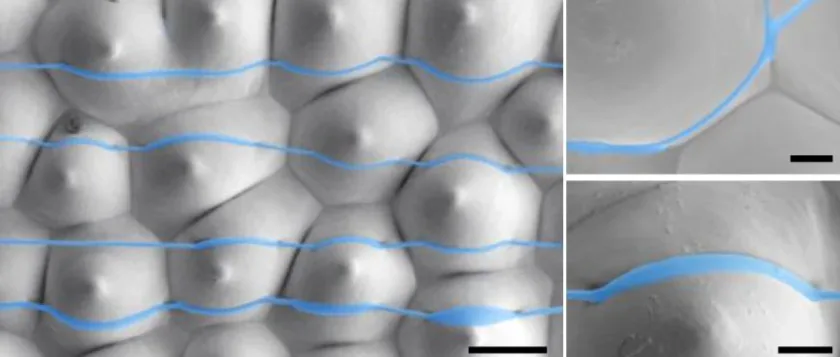

When applied to human skin, these fiber sensors seamlessly conform to its contours. To be more precise, the fibres were able to reveal sweat pores without the wearer noticing their presence.

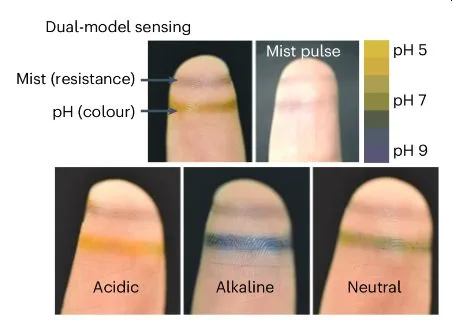

The most intriguing aspect is that initial tests with the fibers applied to a human finger demonstrate exciting potential for continuous health monitoring applications. This suggests they could evolve into compelling tools for various healthcare purposes.

Flexible electronics for Diverse Biological Surfaces

While 3D printing offers an option for creating bioelectronics, it often results in thicker devices that may disrupt normal behavior. So, the innovative electronic fibers developed by the Cambridge researchers can be customized to a wide range of biological surfaces. We have already seen its effortless installation on fingertip to the fluffy seedhead of a dandelion, their adaptability knows no bounds. This versatility holds immense promise for the future.

Takeaway

As its mentioned in the study, the aim is to enhance living structures like human skin and plant surfaces with electronics for health monitoring and environmental observation. This can only be possible if the tech does not interfere with the natural processes. Since its seamless integration has already proved in lab, the potential of bioelectronic fibers appears promising.

If we talk about human sector, continuous health monitoring would revolutionize the management of chronic conditions. As practitioners will get real-time data, they can offer customised and targeting medication without invasive procedures.

Advanced prosthetics and wearable devices can also be leveraged by the integration of bioelectronic fibers.

Additionally, the technology could prove invaluable for agriculture, forestry, and conservation efforts by enabling real-time monitoring of environmental conditions and plant health.

Thus, the study has potential to improve human health and well-being while also advancing our understanding of the natural world.