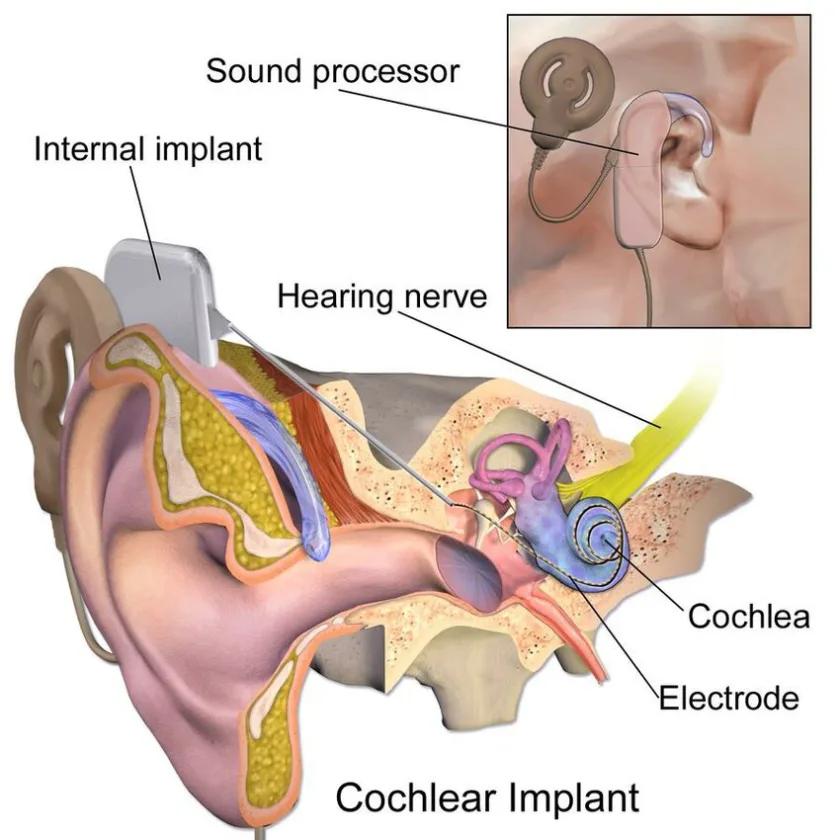

What if a microphone, which is fabricated from a flexible material can be placed inside our ear, to be more specific, directly on the eardrum? This biocompatible sensor will pick up sounds and sends them to a tiny amplifier, which makes the sounds loud enough to be processed by a cochlear implant. Doesn’t it sound like a boon for those who are deaf or hard of hearing?

A multidisciplinary team of researchers at MIT, Massachusetts Eye and Ear, Harvard Medical School, and Columbia University has developed a similar microphone that can be implanted right inside the ear and works just as well as the external microphones used in hearing aids.

Testing in lab environments showed that this system works like traditional hearing aid microphones. But it still needs more work before it can be used as a fully internal cochlear implant.

Tiny Microphone Detects Subtle Eardrum Movements

A tiny microphone made from a special material that generates electricity when it’s squeezed or stretched (generally referred to as piezoelectric material) is used to detect very small movements on the back side of the ear drum. To make sure it works really well, the team also created a special amplifier that boosts the signal without adding much unwanted noise from the electronics.

Cochlear implant microphones are usually put on the side of the head, so users can’t use the outer ear’s natural ability to filter noise and locate sounds. Fully implantable microphones have a lot of benefits, but most of the ones being developed either:

- Pick up sound through the skin

- Sense middle ear bone movements

These methods often struggle to:

- Catch quiet sounds

- Capture a wide range of frequencies

New Microphone Targets Umbo for Enhanced Cochlear Implant Performance

The new microphone design focuses on a part of the middle ear called the umbo. The umbo moves back and forth in a simple way, making it easier to sense its movements. Even though the umbo has the biggest range of movement among the middle ear bones, it only moves a tiny amount, just a few nanometers, which makes developing a device to detect these tiny movements quite challenging.

Any sensor that goes inside the body needs to be made of materials that won’t harm the individual and can handle the wet and constantly changing conditions inside without breaking down. This means there are very few suitable materials to choose from.

The situation is quite similar to a heart monitor that needs to be placed inside a patient’s body. The monitor must:

- Be made from special materials that won’t cause infections or reactions, and,

- Remain reliable while constantly surrounded by fluids and moving tissues.

UmboMic Revolutionizes Cochlear Implants with PVDF Technology

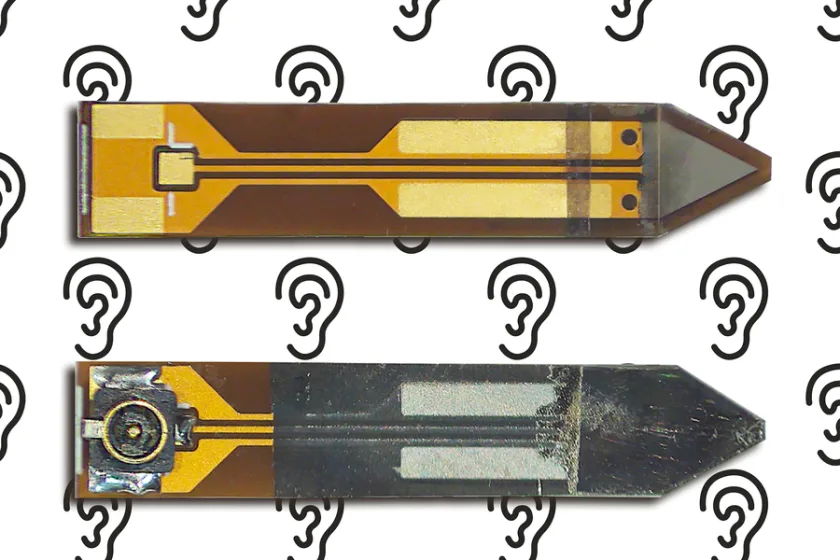

The team figured out how to solve these problems. They built a tiny motion sensor called the UmboMic. It’s shaped like a triangle and measures 3 millimeters by 3 millimeters. That’s about the size of a grain of rice. It’s made of a special material that can generate electricity when it bends, called PVDF. This material is safe for the body.

The UmboMic has two layers of PVDF, with a flexible circuit board in between. The tip of the UmboMic touches a part of the ear called the umbo. When the umbo moves, it makes the PVDF layers bend, creating electric charges. These charges are detected by electrodes in the circuit board.

Innovative PVDF Sensor Design Reduces Noise

The team created a special setup using a material called PVDF to cut down on unwanted noise in their sensor. When the sensor bends, one part of the PVDF makes a positive electrical charge and the other part makes a negative charge. Any electrical interference affects both parts equally, so by comparing the two charges, they can cancel out the noise.

However, PVDF is tricky to work with. It loses its special properties when heated above 80 degrees Celsius, but they needed high temperatures to add a layer of titanium to the sensor. To solve this, one team member added the titanium slowly and used a cooling system to keep the PVDF from overheating.

Even with the sensor built, tiny vibrations were hard to pick up clearly. To make the signal stronger without adding more noise, they needed a very specific amplifier. When they couldn’t find one that met their needs, they designed and made their own.

UmboMic Detects Human Speech Frequencies in Cadaver Tests

Researchers tried out a device called UmboMic on ear bones from cadavers and found it worked well to pick up sounds in the range of normal human talking.

The device, which includes a microphone and an amplifier, can also detect very quiet sounds clearly without being drowned out by background noise.

Scientists Prepare Live Animal Experiments for UmboMic Implantation Research

Scientists are about to start experiments on live animals to understand more about their discovery. They also want to see how the UmboMic performs when it’s placed inside a living body.

They’re working on how to cover the sensor so it can stay inside the body safely for up to 10 years while remaining flexible enough to pick up vibrations. Typically, implants are covered in titanium, but that’s too stiff for the UmboMic. They also need to find a way to fix the UmboMic in place without causing unwanted vibrations.

Takeaway

The future UmboMic looks promising. Firstly, the fully functional implantable cochlear devices would provide users with better sound quality and more effective hearing restoration. Additionally, the use of PVDF and low-noise amplification technology will surely lead to more advanced hearing solutions.

The focus on biocompatibility and durability of the materials used in the UmboMic could set new standards for the safety and longevity of implanted medical devices.

Overall, this research is an interesting and most sought-after advancement in field of biomedical engineering.