I’m excited to introduce Dr. Fengxin Sun, an Associate Professor at the Key Laboratory of Eco-Textile, Ministry of Education, Jiangnan University in Wuxi, China. Dr. Sun completed his Ph.D. in textile materials at Donghua University in Shanghai in 2017 and spent time as a joint Ph.D. student at the Institute for Frontier Materials, Deakin University in Australia. His research covers a fascinating range of topics, from textile material evaluation and functional textile development to mechanical modeling and simulation of soft materials.

Dr. Sun has received numerous accolades for his work, including two First-Class Science and Technology Awards from the China National Textile and Apparel Council. Recently, his research on yarn-based weaving for soft robotics caught my attention, and I reached out to him for an interview. He kindly agreed, and I’m thrilled to share our conversation below!

How did you get into textile materials and when did you start?

I first started exploring textile materials during my postgraduate studies as part of my research, where my focus was on developing in-situ measurement instruments and methods for characterizing the comprehensive mechanical properties of textiles, such as touch sensation and wrinkling performance.

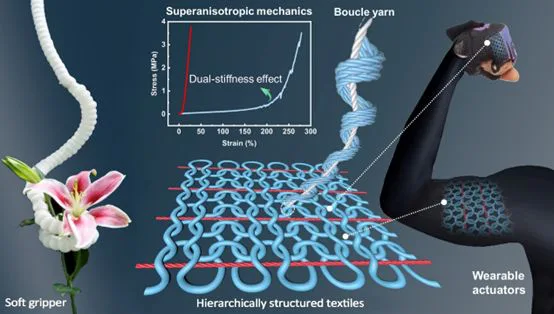

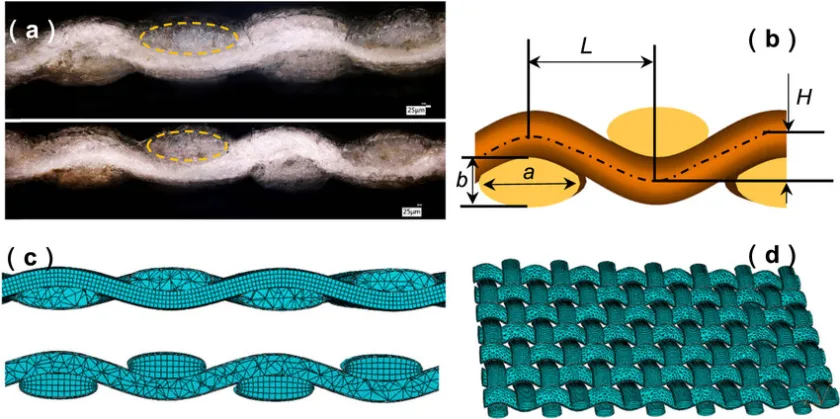

I think most people are familiar with textile materials since we interact with them daily in our clothing, upholstery, and other fabrics. However, even though we encounter textiles regularly, we might not fully appreciate the intricate complexities of textiles. What particularly fascinated me were their unit hierarchical structures, ranging from tiny nano- or micro-scale fibers to large meter-scale fabrics, spanning over six orders of magnitude. It’s amazing to consider that our clothes are made up of these tiny fibers, relying solely on friction to stay together, and that they can even be used to create functional materials and beyond. This intricate structure and unit performance in textiles is what truly captivates me. I now thrive on exploring multilevel structure programming and flexible mechanical analysis of textile materials, applying our customized textiles in soft robotics and scalable fabrication of smart materials.

What initially inspired you and your team to explore the use of a “yarn-to-clothes” approach in developing soft actuators? Ref: Yarn-grouping weaving soft robotics with directional inflation, bilateral bending, and self-sensing for healthcare

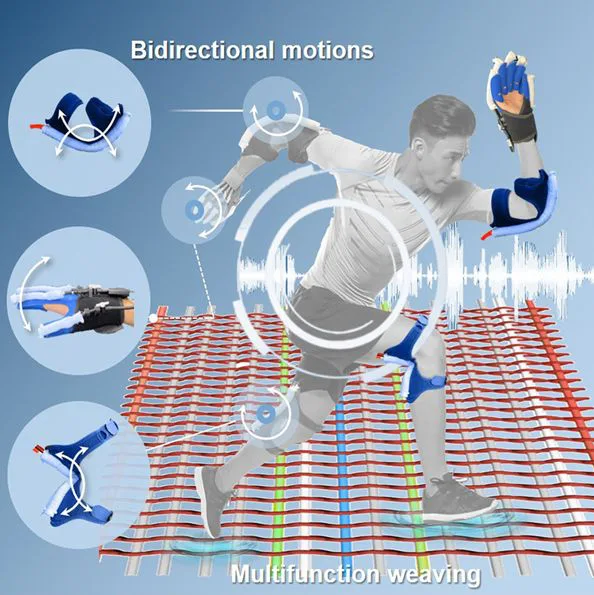

Our exploration into the “yarn-to-clothes” approach for developing soft actuators was largely driven by the limitations we encountered with conventional methods like 3D printing and elastomer casting. These techniques, while effective in certain contexts, didn’t fully meet the requirements for adaptability and comfort in wearable soft robotics. We needed a solution that could seamlessly integrate flexibility, functionality, and cost-effectiveness, while also being easily customizable and scalable.

Inspired by traditional textile manufacturing methods, we turned to a two-system weaving technology. This approach allowed us to integrate both sensing capabilities and actuation modes directly into the fabric of the soft robots’ “garments.” By carefully arranging the warp and weft yarns in a planar layout during weaving, we could easily customize the woven actuators through programming the yarn composition and arrangement. This not only enabled personalized morphing but also provided real-time sensing feedback, making the woven actuators particularly effective for applications such as rehabilitation wearables.

Could you explain how the weaving of yarns—lengthwise and crosswise—enhances the functionality and adaptability of the actuators, especially in comparison to other approaches?

The use of two-system weaving technology in our actuators allows us to precisely control the direction of inflation, which addresses a common challenge in soft robotics known as the “ballooning” effect, where actuators that made by conventional elastomer materials tend to expand uncontrollably in all directions. By weaving the yarns lengthwise and crosswise, respectively, we can easily tailor the actuators to inflate only in the desired directions to enhance the actuation efficiency in a more controlled way

Moreover, our weaving approach offers a flexible and scalable method for fabricating multi-morphing soft actuators. By simply adjusting factors like yarn tension, density, and the woven structure, we can create actuators capable of complex movements, such as bilateral bending, twisting, and spiraling—all under a single air supply.

Can you walk us through the principle of how the TST-F measures the mechanical properties of fabrics? What sets this apparatus apart from other textile testing machines? Ref: Touch Sensation Tester for Fabrics (TST-F)

The TST-F apparatus is designed to measure the comprehensive mechanical properties of fabrics and further characterize their touch sensory attributes by considering their viscoelastic nature. Traditional textile testing machines typically require multiple devices to measure various mechanical properties, such as bending, compression, and stretching, which can be time-consuming and prone to measurement errors due to differences in sensors, devices and samples.

In contrast, the TST-F system offers an advantage by enabling the simultaneous measurement of multiple mechanical properties. It employs a unique in-situ evaluation method that combines temporal and spatial resolution to effectively evaluate the touch sensation of fabrics. During a single test, the TST-F can construct different deformations, including bending, compression, comprehensive recovery, bending recovery, and stretching within a single fabric sample to test the corresponding mechanical information of the fabric. By doing so, it provides a more comprehensive and efficient characterization of fabric handle, all in one cohesive testing process.

Are there plans to further refine or expand the capabilities of the TST-F? For example, can this apparatus be adapted for different types of materials outside textiles, or perhaps more advanced fabric properties like thermal or moisture sensations?

Yes, we have extended the use of the TST-F to evaluate the mechanical properties of various materials beyond textiles, including flexible membranes and papers. Expanding its capabilities to assess other important fabric properties, such as thermal conductivity and moisture sensation, is indeed a valuable research direction, as you suggested. We’ve already begun exploring the thermal property testing with the TST-F to evaluate thermal comfort. Additionally, we are actively working on integrating an image acquisition device with the TST-F. This addition will allow us to simultaneously analyze the constitutive features of samples, including deformation and mechanical behavior, thereby providing a more comprehensive evaluation.

What emerging trends are you seeing in fiber research and development?

I am currently observing significant advancements in the design and research of textile metamaterials, particularly in their applications in smart materials, switchable structures and soft actuators, which closely align with my current interests. Additionally, the sustainable and efficient reuse of waste textiles and fiber materials is also emerging as an important trend.

What are your other interests besides academic commitments and research responsibilities… reading, painting, gardening, skiing maybe?

Painting has always been a passion of mine. I once dreamed of becoming a painter and have been learning Chinese painting and pencil sketching since childhood. Interestingly, I guess that my background in painting may help me effectively express my research through visuals and figures when writing papers.

Someone comes up to you and says, “I wanna be just like you. I want to be a Fiber Scientist. What advice would you give?

Fiber science is a field full of creativity and potential, so if it interests you, then follow that passion. However, stay open to exploring other areas you might not have considered. The advice I can give is to be true to yourself and discover what truly sparks your curiosity and passion.

Quick bits:

What is your favourite movie quote?

My favorite movie quote is “Lift up your smiling face and leave the shadows behind you.” I find this quote inspiring as it encourages positivity and moving forward despite challenges.

If you were a superhero what would your powers be?

If I were a superhero, I would choose super speed. This power would allow me to experience and see more of the world, giving me the chance to learn and explore quickly.

What would you do on Mars for fun?

If I were on Mars, I would have fun learning how to fly in the lower gravity environment.

What will your TED Talk be 10 years from now?

It might be titled “Textiles in the Soft Materials Age”. I think that after the Stone Age, Bronze Age, Iron Age, and Electronic Materials Age, we will enter an era defined by soft materials.

What books should I read in 2024?

If you enjoy science fiction, I would highly recommend The Three-Body Problem by Liu Cixin.

(Wow! Thank you, Dr. Sun, for an incredibly inspiring conversation! Your work is a true source of inspiration. We eagerly anticipate our next visit to witness more of your innovative research. Until then, we extend our best wishes for your continued success in all your future endeavors.)