Robots are quickly making entry into almost all aspects of human work from household to industries, these machines are just everywhere making work easier and faster too. They have also entered in dairy farms, which were so far managed by humans.

The milking process involves certain tasks as collecting cattle, directing them to the parlor, cleaning of teats, attaching milking machines to them, followed by milk extraction, removing the milking machines and directing the cattle out of the parlor. Most importantly to maintain the milk yield, constant milking intervals is required and labor working on dairy farms has to be committed to get up early morning to milk the cattle and again in the evening, seven days a week. This puts a lot of pressure on the labor that has to work consistently regardless of being any situation as personal health, family responsibilities or social event to attend. But thanks to a new automated robotic system, the job can be done autonomously, giving poor labor a life.

Milking robots are now slowly getting popular in the United States. Owner of one such robot-managed dairy farm says that cows like it too. The robot gives the cows with the flexibility to conveniently set their own milking timetable.

Robotic Milking Procedure

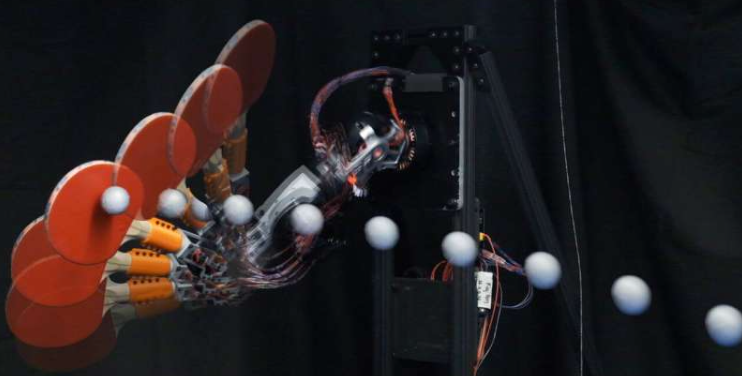

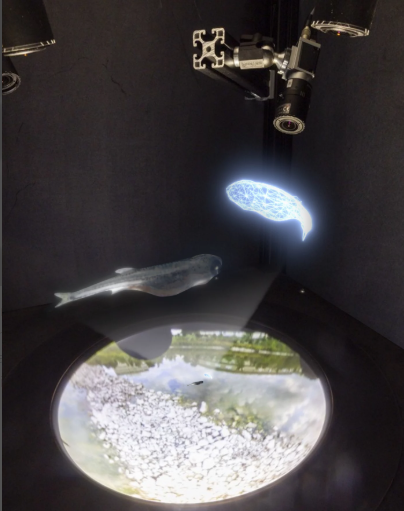

Each cattle are electronically tagged for the bot to individually identify them. As the cow enters the metal stall, it sends signals to the robot to start. These milking robots consist of different parts: a mechanical arm, equipment to clean teats, milking device, computerized display and sensors to find teats location and laser to monitor other details.

The robot first scans the tag of the cow going to be milked and drops feed for the cow in the trough, so that the cows can eat while the milking procedure is carried out. The robot cleans the teats, fixing milking cups and starts milking. These cups are removed post the milking process is complete and the cows leaves the metal stall. The process can be carried out at any hour of the day.

The robot monitors other essential aspects as the amount and quality of milk produced by each cattle. Number of times the animal visited the robot, milking speed, amount of food cow eats and number of steps a cow has ideally walked in a day.

Major Challenges

Most of the dairy farm owners are skeptical to upgrade their farms into automated farms using these robots. They were feared that the milk yield would drop as the cow not used to being milked by a robot, may be reluctant in getting milked. Moreover, the initial set up is also expensive, costing around $250,000 for a machine. Breakdown of machines and learning to get used to new technologies were major challenge for most of the dairy farmers.

However, according to seventh generation diary men, Mike Borden, who has installed milking robots in his farms, says he is happy and content with his decision of farm up-gradation. He says that after initial training, the cows started accepting the robotic system and slowly the process was fully automated, requiring minimal human intervention also finding reliable labor is very difficult. These robots have saved him from incurring labor costs such as health insurance, overtime, providing room and staying facility, insurance and other compensation. Moreover, unlike humans, robots never complained of working overtime.

Borden further added that employing milking robots have relaxed the cows and routine in his farms. The robots also call in human interaction in case some problem arises. But then even human labor gets sick and have other personal problem, but we do not panic under such situation. At least the machines can work round the clock. These robots have helped the dairy owners to achieve three milking per day, thus increasing the productivity at the same cost. Most importantly, the new system offers the dairy owner a chance of attending family functions with his entire family, travelling and outing, knowing that the milking robot is talking care of dairy farm in his absence, privileges which were absent before.

Source: The New York Times